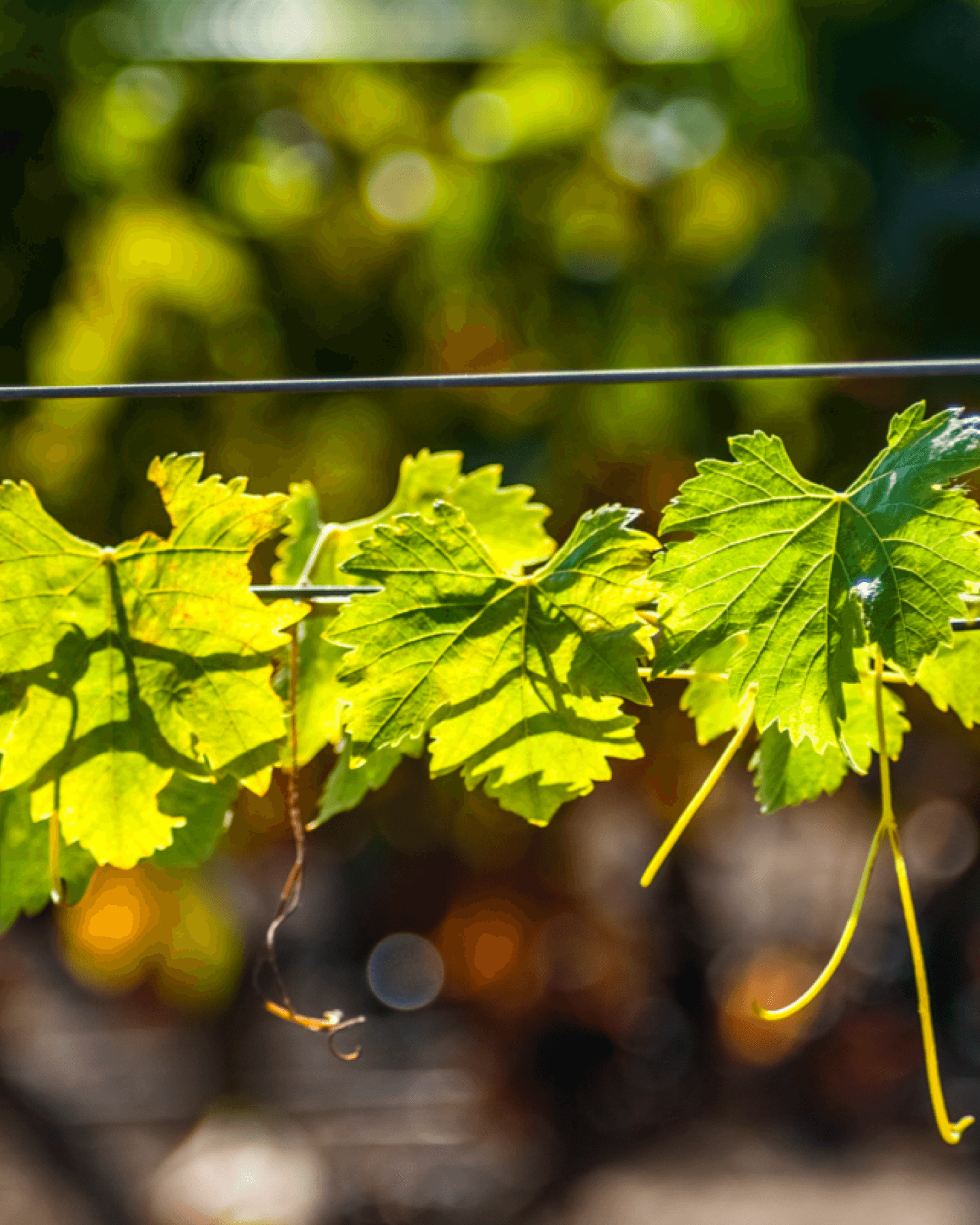

Exacting standards and precision are to be found at all stages of the making of Mapu.

The patchwork of terroirs from which the wines come, as well as the men and women who tend the vines, need to be preserved and respected, as does the consumer.

Baron Philippe de Rothschild Chile has Sustainable Wine of Chile certification, a voluntary scheme encompassing three areas: vineyard, process and corporate. Run by the Chilean wine industry, it is perfectly suited to vinegrowing and winemaking in Chile. The certification is defined, regulated and awarded by the Chilean wine council, Wines of Chile.